+7 86342 3-59-86

+7 86342 3-59-58

Machines for

gentle cleaning

and calibration

of grain

Manufacture of machines for gentle cleaning and calibration of grain

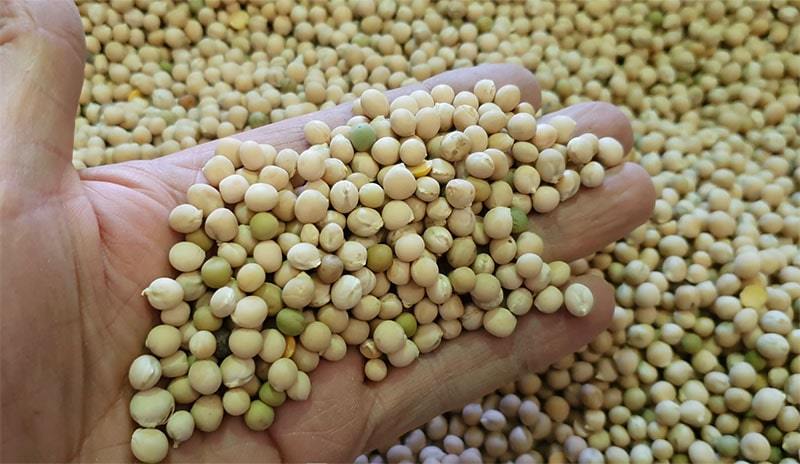

Cleaning and calibration of:

Wheat

Rye

Oat

Barley

Buckwheat

Corn

Sunflower

Flax

Peas

Chickpea

Corriander

Soy

You get the purest grain and the best seeds!

Our machines

Grain cleaning machines

AZIMUT aerodynamic machines

AZIMUT machines provide:

- Primary cleaning of grain crops from various debris and impurities.

- High-quality seed material according to the specific weight and size of all crop seeds.

Vibration calibration

ZHUZHA vibrators

ZHUZHA machines are designed for:

- calibration of grain according to grain size.

- cleaning of grain from impurities and debris

Belt elevator

Low-speed seed elevator NTS 10-60 t/h

Low-speed NTS elevator:

- for vertical lifting of grain and other bulk materials, for loading into hopper containers located at a height of 3 to 18 meters or higher,

- At the same time, there is no injury to the grain material.

Video: the way our machines work

New machines are being prepared for release

pre-sowing grain processing

№1: Z-shaped elevator

№ 2: The machine for wet and anti-bacterial preparation of grain before sowing (for greater sustainability in arid lands)

№ 2: The machine for wet and anti-bacterial preparation of grain before sowing (for greater sustainability in arid lands)

3 key advantages of AZOVSELMASH:

Our machines don't crush grain!

You can try out the machines before purchasing!

Grain processing line

1

2

3

Preparation of grain for sowing, with the seeds showing 99% germination!

Grain is not injured due to the original design of the machines

Bring on your grain, evaluate how it is cleaned and calibrated

Request a consultation for grain cleaning and calibration machines

Leave your phone number, we will call you back and answer all your questions

The problems of the farmer:

1. Broken grain - up to 30%

2. Grain with debris

The more debris and broken grain, the cheaper the material

Solution:

1. Whole grains

2. Pure selected grain

The cleaner the grain, the more expensive it is

Machines by AZOVSELMASH

The problems of the farmer:

1. Broken grain - up to 30%

2. Grain with debris.

The more debris and broken grain, the cheaper the material

Solution:

1. Whole grains

2. Pure selected grain

The cleaner the grain, the more expensive it is.

Machines by AZOVSELMASH

Grain processing line

The processing line for seed preparation must have the technical capacity to prepare seeds for planting, which would have a germination rate of 99% .

That is, almost every grain should give sprouts, then the harvest will be as rich as possible.

For this, the seeds before planting must be carefully selected, grain should not be broken, undersized grain and debris should be excluded, the uniformity of the grains should be maximized – this will allow the seeder to plant seeds in the same way.

At the entire stage of seed preparation, it is important to avoid any injury to the grain.

We offer such a processing line and today it can be available to every farmer.

Our grain processing technology is efficient, only when our machines are installed in the process chain, with the grain protected from injury at each processing stage.

Using low-speed seed elevator NTS, grain is loaded into AZIMUT grain cleaners, where it is cleaned according to weight and volume, and then proceeds by gravity or via a low-speed bucket elevator NTS, or a Z-shaped bucket elevator sent to ZHUZHA vibrator for selection of grain by size.

As a result, you get a refined non-broken grain, selected by weight and size.

On request, a grain dryer is also installed in this chain.

That is, almost every grain should give sprouts, then the harvest will be as rich as possible.

For this, the seeds before planting must be carefully selected, grain should not be broken, undersized grain and debris should be excluded, the uniformity of the grains should be maximized – this will allow the seeder to plant seeds in the same way.

At the entire stage of seed preparation, it is important to avoid any injury to the grain.

We offer such a processing line and today it can be available to every farmer.

Our grain processing technology is efficient, only when our machines are installed in the process chain, with the grain protected from injury at each processing stage.

Using low-speed seed elevator NTS, grain is loaded into AZIMUT grain cleaners, where it is cleaned according to weight and volume, and then proceeds by gravity or via a low-speed bucket elevator NTS, or a Z-shaped bucket elevator sent to ZHUZHA vibrator for selection of grain by size.

As a result, you get a refined non-broken grain, selected by weight and size.

On request, a grain dryer is also installed in this chain.

In fact, the processing line solves almost all the problems of the farmer's pre-sowing seed preparation.

The line consists of:

1) low speed seed elevator (NTS), with or without a scraper loader.

2) AZIMUT aerodynamic machine

3) Intermediate elevator (NTS) (in some cases, it is optional)

4) ZHUZHA vibrator

5) Discharging elevator (NTS) or Z-shaped (seed) elevator

6) The machine for wet and anti-bacterial preparation of grain before sowing for greater sustainability in arid lands (the machine is being prepared for release)

The line consists of:

1) low speed seed elevator (NTS), with or without a scraper loader.

2) AZIMUT aerodynamic machine

3) Intermediate elevator (NTS) (in some cases, it is optional)

4) ZHUZHA vibrator

5) Discharging elevator (NTS) or Z-shaped (seed) elevator

6) The machine for wet and anti-bacterial preparation of grain before sowing for greater sustainability in arid lands (the machine is being prepared for release)

OUR MACHINES PAY FOR THEMSELVES AT THE FIRST 1000 TONS!!!

Production

Our production is located in the city of Azov.

2000 m2 of production space:

- welding area

- assembly site

- painting facility

- testing area for customers when purchasing a machine (the customer tests the machine operation with their own grain)

2000 m2 of production space:

- welding area

- assembly site

- painting facility

- testing area for customers when purchasing a machine (the customer tests the machine operation with their own grain)

Company info

My desire to be engaged in production appeared a long time ago, when I was living in Georgia and working at a seed farm, and even then there was a problem with the integrity of seeds during grain processing.

Director of LLC AZOVSELMASH Yuri Ivanovich Arishin:

Consultation

on grain cleaning and calibration machines

on grain cleaning and calibration machines

Call us at +7 (86342) 3-59-86

Or leave your phone number, we will call you back and answer all your questions

Or leave your phone number, we will call you back and answer all your questions

Нажимая на кнопку, вы даете согласие на обработку своих персональных данных

Contact info

AZOVSELMASH

Russia, Rostov region, Azov, Druzhby str. 52

+7 (86342) 3-59-86

+7 (86342) 3-59-58

+7 (958) 544-69-09

mail@azovselmash.com

Russia, Rostov region, Azov, Druzhby str. 52

+7 (86342) 3-59-86

+7 (86342) 3-59-58

+7 (958) 544-69-09

mail@azovselmash.com

AZOVSELMASH

Russia, Rostov region, Azov, Druzhby str. 52

+7 (86342) 3-59-86

+7 (86342) 3-59-58

+7 (958) 544-69-09

+7 (86342) 3-59-58

+7 (958) 544-69-09

mail@azovselmash.com

Contact info

Personal info

Content Oriented Web

Make great presentations, longreads, and landing pages, as well as photo stories, blogs, lookbooks, and all other kinds of content oriented projects.

We will call you

and we will answer all your questions. To do this, leave your phone number and comment